Dingbang science and technology equipment exported to many countries

发布时间:

2024-05-11 18:43

Vacuum metallurgy in the field of non-ferrous metal metallurgy has the characteristics of high resource utilization, short process flow, low production cost and low energy consumption. It is a clean and efficient metallurgical technology. Looking at its application prospects in the industrial field, in 2005, Kunming Dingbang Technology Co., Ltd. was formally established, and launched in-depth industry-university-research cooperation with Kunming University of Science and Technology, focusing on the extraction of non-ferrous metals from metallurgical raw materials, non-ferrous metal secondary resource regeneration, and high purity Research on the preparation of non-ferrous metals has been carried out, and a number of major scientific and technological achievements have been made in the field of vacuum metallurgy technology industrialization.

"Whether it is from the process, economic indicators, or from the perspective of systematic application, vacuum metallurgy technology is more superior." Dai Weiping, chairman of Dingbang Science and Technology, said that taking the crude selenium vacuum refining system built by the company as an example, after the crude selenium slag material produced in the copper smelting process enters a special vacuum selenium melting furnace, the crude selenium melt is distilled in the vacuum furnace and finally becomes crude selenium metal melt and residual slag, of which crude selenium metal becomes refined selenium after refining, and the residual slag becomes recoverable precious metals such as gold and silver, thus realizing high-value utilization of the material. The equipment solves the pollution problem, shortens the process flow, and greatly improves the metal recovery rate. Compared with the traditional crude selenium refining process, the treatment capacity is increased by more than 4 times.

Since 2006, Dingbang Science and Technology has focused on the industrialization research and development of vacuum metallurgy technology and the promotion of achievements. It has successively developed new processes and new equipment such as crude tin vacuum refining and purifying tin, hot galvanizing slag vacuum distillation to extract zinc, crude indium vacuum purifying indium, crude cadmium vacuum refining cadmium, etc. Among them, the new technology and industrial application of complex tin alloy vacuum distillation won the second prize of the 2015 National Science and Technology Progress Award (ranked first); cadmium pollution prevention and cleaner production extraction key technology and equipment application demonstration project won the China Nonferrous Metals Industry Science and Technology Award. At present, Dingbang Technology has more than 40 technologies of various types, and was listed on the "New Third Board" in 2017. Independent research projects such as non-ferrous metal vacuum melting, distillation furnace, and waste aluminum alloy vacuum melting and purification technology are expected to be implemented this year.

Dai Weiping said that technological innovation is the vitality of enterprise development. As an enterprise aiming at technological innovation and industrialization of vacuum distillation metallurgy, Dingbang Technology established a "two-legged walk" business strategy in 2018 to further strengthen the research and development, manufacturing and technical services of non-ferrous metal vacuum metallurgy equipment, and to use independent research and development technological achievements to enter the field of non-ferrous metal high-purity materials and new material preparation. In 2021, 58 million yuan will be invested in the research and development of new materials and development of new materials and recycling. At present, the company's new technological achievements have been applied to global non-ferrous metal smelting enterprises, non-ferrous metal resource recycling enterprises and non-ferrous metal new material preparation fields. Complete sets of vacuum metallurgy equipment are exported to Europe, the United States, Russia, Japan, Malaysia and other countries and regions.

Dingbang science and technology equipment exported to many countries

2024-05-11 18:43

Vacuum metallurgy in the field of non-ferrous metal metallurgy has the characteristics of high resource utilization, short process flow, low production cost and low energy consumption. It is a clean and efficient metallurgical technology. Looking at its application prospects in the industrial field, in 2005, Kunming Dingbang Technology Co., Ltd. was formally established, and launched in-depth industry-university-research cooperation with Kunming University of Science and Technology, focusing on the extraction of non-ferrous metals from metallurgical raw materials, non-ferrous metal secondary resource regeneration, and high purity Research on the preparation of non-ferrous metals has been carried out, and a number of major scientific and technological achievements have been made in the field of vacuum metallurgy technology industrialization.

Major events in magnesium industry

2022-01-19 11:39

2021 is the 100th anniversary of the founding of the Communist Party of China and an extraordinary year for the magnesium industry. Magnesium alloy materials have helped the "tianwen-1" probe successfully land on the surface of Mars, the Tianhe core module enters the space station, the application of magnesium battery materials and magnesium building templates, and the green and low-carbon development of magnesium smelting. The major events of this year's magnesium industry are like knots on a long rope, which string up the flowing time, which is unforgettable and worth remembering for a long time.

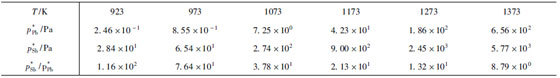

Experimental study on vacuum distillation of lead antimony alloy

2022-01-19 11:35

It is of great significance to recycle the lead antimony alloy produced in the smelting and consumption of lead and antimony. In this paper, the saturated vapor pressure, separation coefficient and gas-liquid equilibrium composition diagram of pure lead and pure antimony in the temperature range of 923 ~ 1373 K are calculated. The feasibility of vacuum distillation separation of lead antimony alloy is analyzed from the perspective of thermodynamics.

Nonferrous Metal Industry: strengthening muscles and bones in "jubilant"

2022-01-19 11:29

As an essential basic material and important strategic material for national economic development, the development trend of non-ferrous metal industry in 2021 can be described as "jubilant". "From January to November 2021, the output of 10 kinds of common non-ferrous metals reached 59.107 million tons, a year-on-year increase of 6.3%. The total investment in fixed assets increased by 6.9% year-on-year. The profits of non-ferrous metal enterprises above Designated Size reached 341.01 billion yuan."

Copyright © 2022 Kunming Diboo Technology Co., Ltd., Website building:Chinese Enterprise Power Kunming case number:NO.12002058-1 ICP BEI SEO